HOW?

We think the banana fruit is packed in a perfectly natural package, developed over millions of years. The banana peal – or skin – was the inspiration when we got the idea for a truly sustainable packaging material – banana paper!

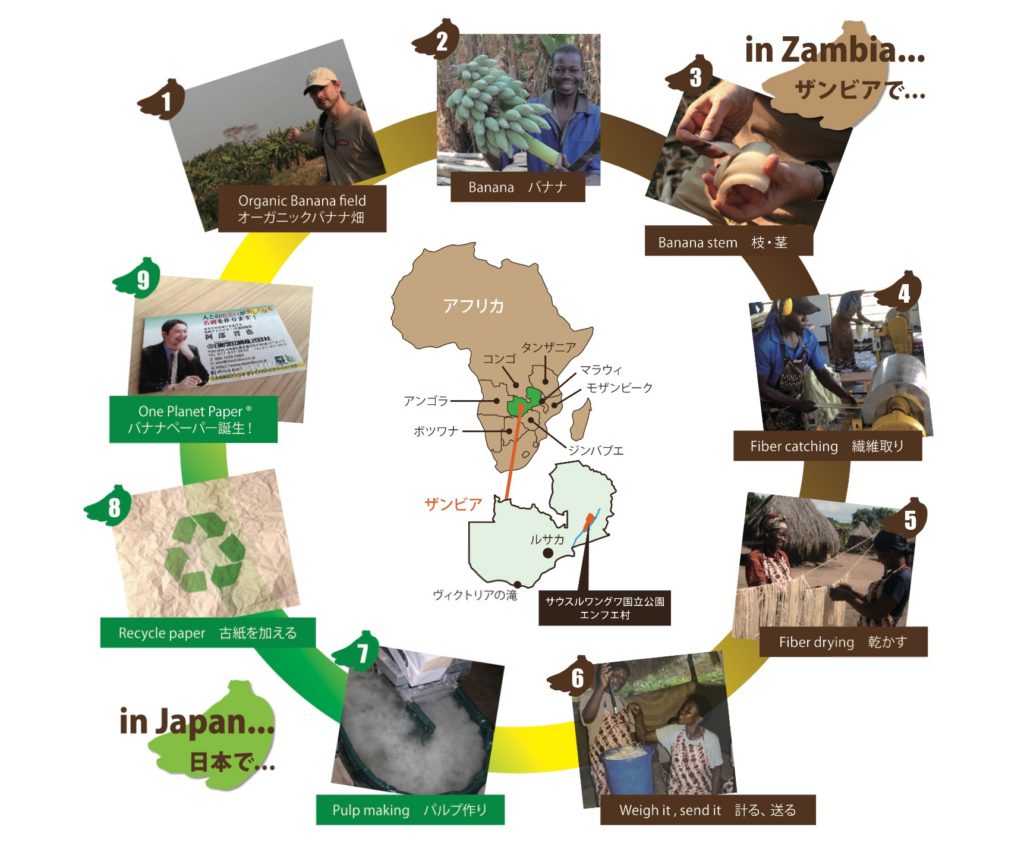

Biomimicry inspired us. We found out that banana trees become fully grown in just one year – compared to 7-30 years for conventional tree-paper. Only one bunch of banana fruit grows per tree. After harvest, farmers must cut the “mother stem” to allow 2-3 new banana shoots to grow and produce new fruit. This cycle all happens in one year!

■ It all started in 2010…

The cut stems usually end up as waste at the farms. When we got the idea of making banana paper we asked organic banana farmers if we could buy their discarded stems.

“It’s waste.” they said. “And we don’t believe you can make paper from it anyway, so we give it to you for free!” When we told about Fair Trade, they finally agreed to receive a fee for their stems.

Inside each stem, there are fibers – the basic ingredient to produce paper. We bring the stems to our Green Factory in Zambia, where we train local people from the villages to extract the fiber.

Today we collaborate with more than 50 organic banana farmers who can now sell both their fruit AND its waste. This adds value to their crops, often doubling their income.

Our goal was to find a “business that can make a social and environmental impact”. Today the banana paper project creates fair trade employment for 23 local people (Nov 2022). Over 1000 people from extreme poverty areas, benefit from the project.

In other words: banana paper add value to agricultural left-overs, ceating a green economy based business that helps reduce both extreme poverty and environmental problems.

■ Ingredients

Our banana paper is made by hand in Zambia, and by machine in Japan and UK. At a small-sized traditional washi factory in Japan, the paper is made by mixing 5%-20% banana fiber with recycled paper, and 5%-20% banana fiber with environmentally certified paper (FSC). In both Zambia and UK we use 25% banana fiber mixed with recycled paper. We do not allow any factory to mix so called virgin pulp (from non-certified trees) into our banana paper.

The final paper brand is called One Planet Paper® . It follows WFTO (World Fair Trade Organization) criteria with over 200 points towards sustainability.

■ Is it possible to create a truly sustainable paper?

This is our goal. After all, trees may be renewable but forests are not. We need a positive alternative to tree-paper.

We have already connected the banana paper to the 17 Global Goals, become Fair Trade verified (2016) and Climate Positive (2021) reducing extreme poverty and environmental problems at the same time as we fight climate change protecting forests and wildlife directly on the ground.

The banana paper project is a unique collaboration between banana farmers & villages in Zambia, and traditional paper factories in Japan and Europe. Run by environmental experts.

■ How banana paper is made

The result is a beautiful paper with the texture of traditional Japanese washi-paper. Our banana paper is now sold and used in 20 countries worldwide (Nov 2022). We will continue to improve in terms of technology and price so that banana fiber can be used even more.

Trees regenerate in 7-30 years, but banana plants in just 1 year. The left-overs from banana farms become a new resource!

Sun-drying the extracted fiber in Zambia | The washi paper factory in Japan