WHY banana paper?

Trees are renewable, forests are not.

We want you to think about how your paper was made. What forest did it come from? What animals live there?

After all, we ask those questions about the food we eat and the clothes we wear.

Paper face similar challenges as food and clothes – like fast paper and paper loss. Did you know we use over 1 million tons of paper every day on our planet? *4. Around 90% of this paper comes from trees…

We want to give people, companies and the paper industry a fun and Fair Trade alternative that not only act on reduce the ecological footprint, (e.g less waste, CO2 and water usage), but also increase the ecological handprint (e.g more trees, wildlife and renewable energy). One Planet Paper® is a product inspired by nature (biomimicry), upcycling agricultural waste from organic banana farms. So let’s “go bananas” with us!

■ Fair trade and the Global Goals

In 2010 we had a half-crazy idea: Finding a way to produce “a paper that can help reduce both extreme poverty and environmental problems” at the same time.

We did not come from the paper industry, but from a bckground as environmental experts (activists). We had visited the biodiversity “hot spot” of Zambia where we saw wonderful wildlife but also extreme poverty – and lots of small scale banana farms. Back in Tokyo, we approach printing fiems, paper product makers, and small-scale paper companies. They admitted that a more ethical and sustainable alternative to tree paper – sooner or later – was going to be necessary. The rest is history…

In 2015, we connected the banana paper to all 17 Global Goals (SDGs).

In 2016, banana paper became one of the first Fair Trade verified (labeled) paper.

In 2020, we were recognized by Japans Ministry of Finance as one of Japans good examples towards the Global Goals

In 2021, banana paper became Climate Positive.

In 2022, a Generation Z survey in Japan chose us (One Planet Café) as one of the top ethical companies.

In 2023, we collaborate with small scale paper mills in both Japan and UK to produce a high quality and Fair Trade banana paper being sold in 20 countries.

■ Who made your paper?

The question “Who made my…?” is today common for the clothes we wear to the food we eat. But honestly, paper? Who made the paper in our notebooks? What kind of life do they live – and what animals live in the forests that this paper originates from? This is one of many questions we asked when we started our banana paper journey with the aim at “putting a face on the paper”.

From the first stages in Zambia (banana fiber) to the last stages (return to soil *2), sustainability was integrated step by step. Source: *1 WFTO World Fair Trade Organization Certification 2020 / BioCarbon Partners, VCS Verified Carbon Standard Certification 2021 | *2 Biodegradable composting experiment, Japan 2021 (to soil within 2 weeks)

■ Why Japan?

Japan’s paper production is the third largest in the world after China and the United States. The per capita consumption is more than 200 kg per year. For example, in the case of printing (copy) paper, 1 in 5 sheets comes from delicate tropical froests (including rainforests) *5. In total, we are losing more forests than are being regenerated *6. The impact can be huge…like endangered species living in forests (tigers, elephants, orangutans etc.) and destruction of ecosystems. And when we lose forests, we also lose the ability to absorb enough CO2…

Deforestation also leads to poverty in developing countries who rely on forests for food, fuel, and income.

We have seen this with our own eyes. We work directly on the ground with the local communities in producing banana paper, conserve forests and wildlife.

Source: *3 Statista 2019 | *4 Market Pulp Association 2007 | *5 WWF Japan “Is Tree Paper Eco-friendly?” 2020 | *6 FAO United Nations 2020

■ Sustainable paper today?

Recycled paper and FSC-certified paper are some of the few solutions towards sustainable paper today. We believe it can be pushed further! Paper may sound boring, but doing it sustainability correct, can contribute to not only a better environment, but also create a positive social impact. That’s why we call our banana paper One Planet Paper®︎.

■ Circular Paper

A comprehensive circular product needs to connect with the following TWO cycles:

(1) Technical Cycle. This is the Human-made cycle where we find the 3R: Reduce, Reuse, Recycle

(2) Bio Cycle. This is the Nature-made cycle created by nature. Here we find the more advanced 2R: Recover and Return.

One Planet Paper®︎ is incorporating both those cycles.

It usually takes about 7 to 30 years for a tree to grow to a sufficient size. On the other hand, banana trees (“herb” to be precise, it is called a “stem”) grows in just one year. Moreover, each tree bear fruit only once per tree. And only ONE bunch of bananas per lifetime. When harvesting bananas, the mother stem must be cut to allow 2-3 new “banana babies” (shoots) to grow up.

In other words, you give back MORE to nature than you take (the bio cycle).

The newborn banana babies the grow up (regenerate) within one year.

It’s the disposed of banana tree we make the banana paper from. It cpntains hogh quality fiber – the basic ingredient to paper. We the disposed of trees from the local banana farmers, enabling them to earn an income of both the fruit and the waste!

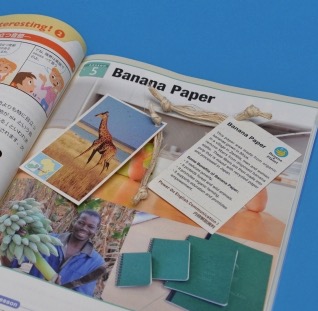

Yes. We think one of the most fantastic things with banana paper, is that it also create a healthy food source for people living in extreme poverty areas.  The above photos are taken by our Team. It shows organic banana fields, banana stems, and wildlife in Zambia.

The above photos are taken by our Team. It shows organic banana fields, banana stems, and wildlife in Zambia.

OnePlanet Paper® uses fibers from stems that are usually discarded in Zambia’s organic banana fields, adds recycled paper to a washi factory in Japan, and a historic paper mill in UK, to produce high-quality paper. This exciting new paper can not only help to solve poverty in developing countries, but also pass on traditional paper skills im Japan, creating jobs in both developing and developed parts of the world.